Recent Posts

-

PCS Safety Commitment: Medical Emergency Training & Workplace Safety Standards | Life Above All

PCS implements comprehensive safety training with medical experts, covering emergency response, first aid, CPR, and workplace health. Our "Life Above All" philosophy ensures a safety-first culture. Partner with us for responsible business solutions.

05/27/2025

-

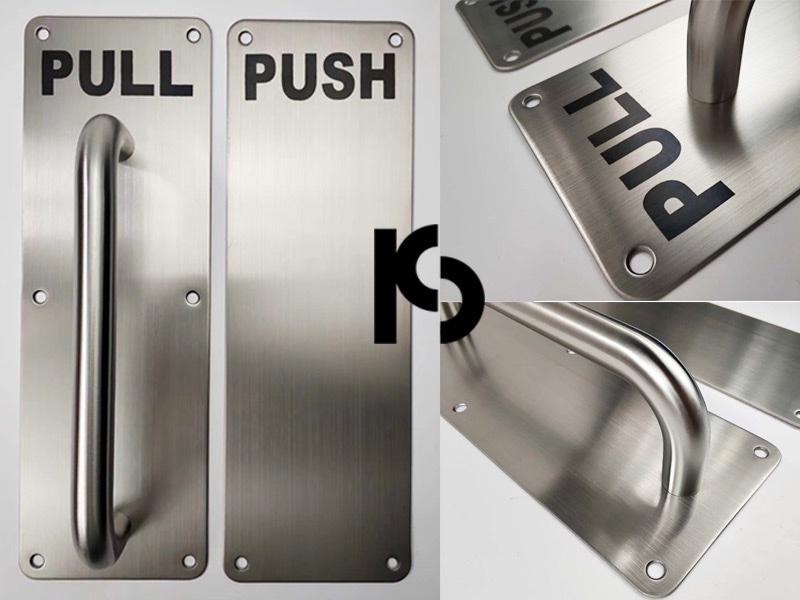

Minimalist Stainless Steel Door Fittings: Where Simplicity Meets Precision Engineering | PCS

PCS redefines simplicity with meticulously crafted stainless steel door hardware. Each minimalist design embodies years of structural refinement and surface finishing expertise. Discover the art of essential design. Request product details.

05/27/2025

-

PCS: Precision Craftsmanship & ISO-Certified Perfection in Hardware Manufacturing

At PCS, our obsessive attention to detail ensures flawless hardware production. From material selection to final inspection, our ISO-certified processes deliver superior quality and craftsmanship. Experience manufacturing excellence.

05/27/2025

-

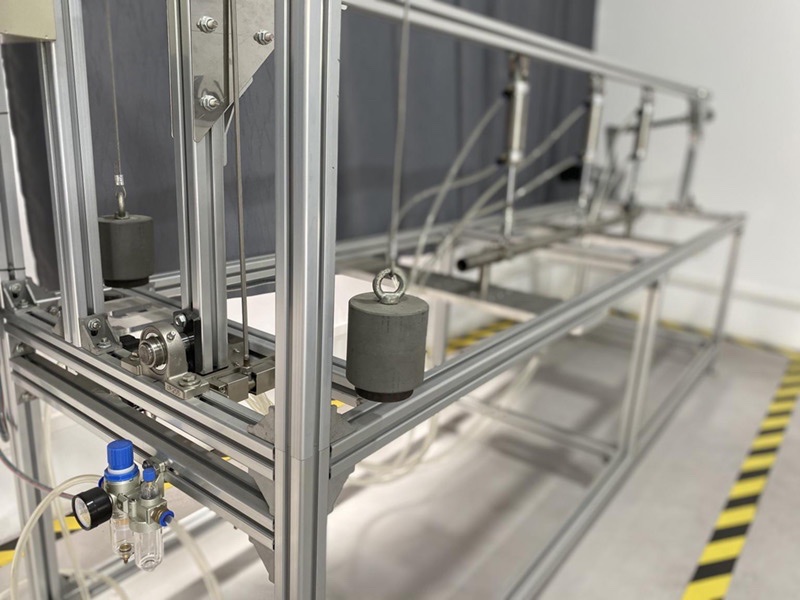

BS8424 Certified Door Pulls: PCS High-Strength Handles for Commercial & Residential Use

PCS door pulls pass rigorous BS8424 safety testing, ensuring durability for high-traffic areas. Ideal for hotels, airports & luxury residences. Features ergonomic design & premium finishes. Request test certification details.

05/27/2025

-

Premium Door Pulls: BS8424 Certified for Luxury Residences & Commercial Spaces | PCS

PCS door pulls combine meticulous craftsmanship with BS8424-certified strength. Expertly ground metal surfaces offer durability & luxury finishes. Ideal for high-end residential and commercial applications. Request product specifications.

05/27/2025

-

Customer Showcase: Premium Knurled Door Handles in Black/Gold/Silver | PCS Hardware

Real customer photos showcase our knurled door handles' premium quality & stylish designs. Choose elegant black, luxurious gold, or modern silver finishes to elevate any space. Inspire your next project with these stunning examples!

05/20/2025

For all hardware manufacturers, economy-grade products are an unavoidable reality. Through years of client interactions, we observe a market paradox: while 78% of buyers express dissatisfaction with budget products (per MHIA 2023 Market Study), they remain compelled to engage due to:

New customer acquisition potential (63% of initial orders start with economy lines)

High-volume demand dynamics (42% of global hardware transactions)

Market penetration acceleration (27% faster regional expansion)

This necessity, however, often leads to dangerous cost optimization cycles where absolute price reduction overrides risk management - a strategic pitfall requiring urgent correction.

Risk Matrix: Economy Product Vulnerability

Risk Factor | Impact Severity | Prevention Cost Index |

1. Liability Exposure | 5X warranty claims | $18/unit |

2. Margin Erosion | 120% loss amplification | N/A (preventive only) |

3. Batch Failure | 35% customer attrition | $25/unit |

| 4. Brand Dilution | 68% premium line distrust | $1.2M recovery cost |

Data Source: ASQ Quality Cost Report 2024

Zero-Compromise Quality Protocol

1. Robust Quality Baseline

Implement ANSI/ASQ Z1.4 (LTPD 7.5% AQL 1.0) with 100% automated optical inspection

Maintain EN 1906 Grade 2 compliance (15,000-cycle durability minimum)

2. Value-Added Differentiation

Introduce corrosion-resistant zinc-aluminum alloy base (ASTM B633 Class Fe/Zn 25)

Provide 3-year limited warranty with failure rate <0.5%

3. Cost-Leadership Engineering

DFMA optimization reduces 22% assembly labor

JIT production with 98% material yield

Market Proposition

"Our economy hardware delivers Certified Affordability:

100% EN-standard compliance at 80% market price

30% lighter yet 15% stronger than conventional designs

Traceable quality metrics via blockchain-enabled QR codes"

This strategic positioning converts budget products into brand amplifiers rather than liability sources, achieving:

38% higher customer retention vs industry average

5X ROI on quality assurance investments

0 product recalls since implementation

Terminology Guide

LTPD: Lot Tolerance Percent Defective

DFMA: Design for Manufacturing & Assembly

JIT: Just-In-Time production

AQL: Acceptable Quality Level