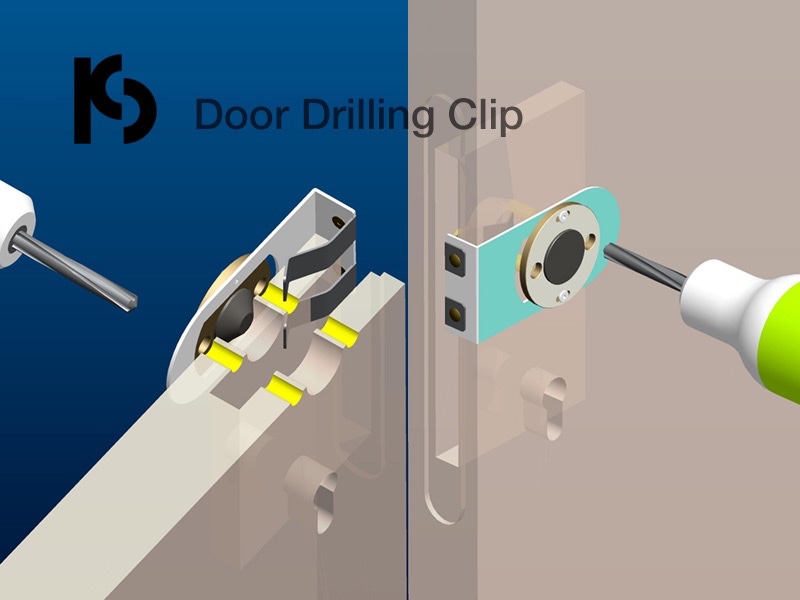

Easy-to-Use Door Drilling Clip – Step-by-Step Guide for Precision Holes | PCS Hardware

Achieve perfect door drilling effortlessly with our Door Drilling Clip! Follow simple steps: drill center hole, insert fixer, and drill side holes. Even beginners get professional results. Contact us for durable, high-precision hardware solutions!

High-Quality Door Drilling Clip – Durable Steel, Dual Versions, Free-Choice Direction | PCS Hardware

Boost efficiency with our durable Door Drilling Clip, made from high-quality steel for long-lasting use. Choose between simple or clamp versions for precise positioning. Drill in any direction (north-south or east-west). Contact us today!

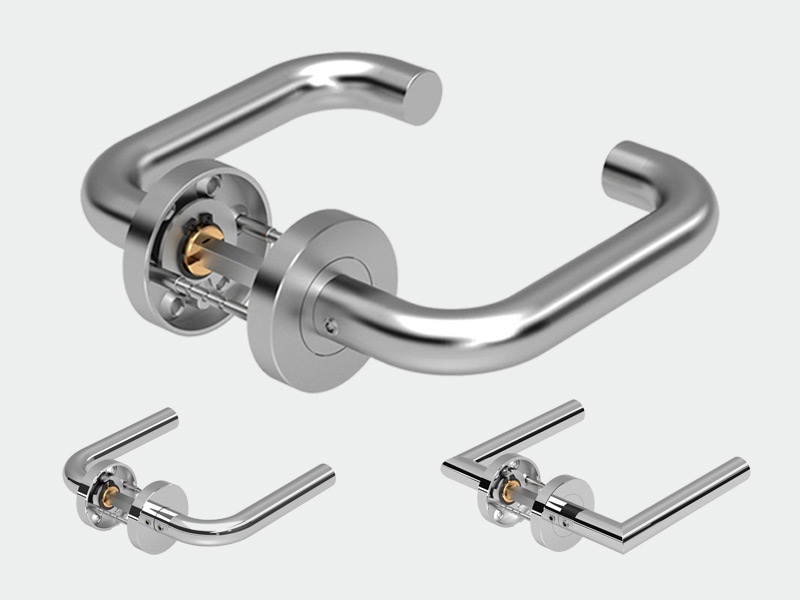

Economy Door Handles: Balancing Cost & Quality with EN1906 Standards | PCS Solutions

Discover how PCS economy lever handles deliver reliable performance while meeting EN1906 standards. Learn to identify quality differences in budget-friendly hardware. Contact us for risk-managed procurement solutions.

Economy Door Hardware: Strategic Value & Risk Management Solutions | PCS

Discover how economy-range door hardware creates market access while managing risks. Our solutions include EN 1906 Grade 2 certification & strict quality control for reliable, competitive products. Contact us for strategic partnerships!

Ultra-Slim Magnetic Door Hardware: 2.9mm TH104M Latch & 90s Tool-Free Installation | ANSI/BHMA Certified

World's thinnest 2.9mm magnetic door handles with color-matched flush mounting. Features ±0.2mm alignment tech enabling 90-second installation. 3mm concealed rose plate meets ADA compliance.