Recent Posts

-

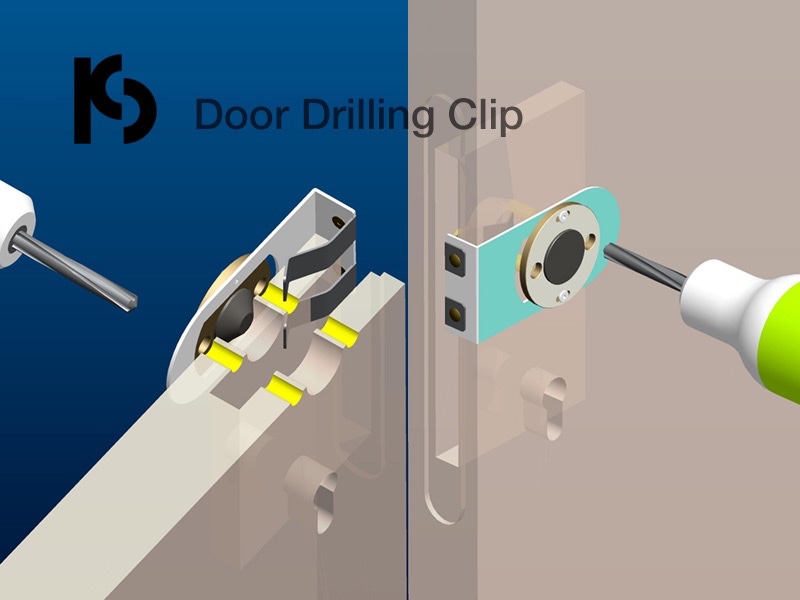

Easy-to-Use Door Drilling Clip – Step-by-Step Guide for Precision Holes | PCS Hardware

Achieve perfect door drilling effortlessly with our Door Drilling Clip! Follow simple steps: drill center hole, insert fixer, and drill side holes. Even beginners get professional results. Contact us for durable, high-precision hardware solutions!

-

High-Quality Door Drilling Clip – Durable Steel, Dual Versions, Free-Choice Direction | PCS Hardware

Boost efficiency with our durable Door Drilling Clip, made from high-quality steel for long-lasting use. Choose between simple or clamp versions for precise positioning. Drill in any direction (north-south or east-west). Contact us today!

-

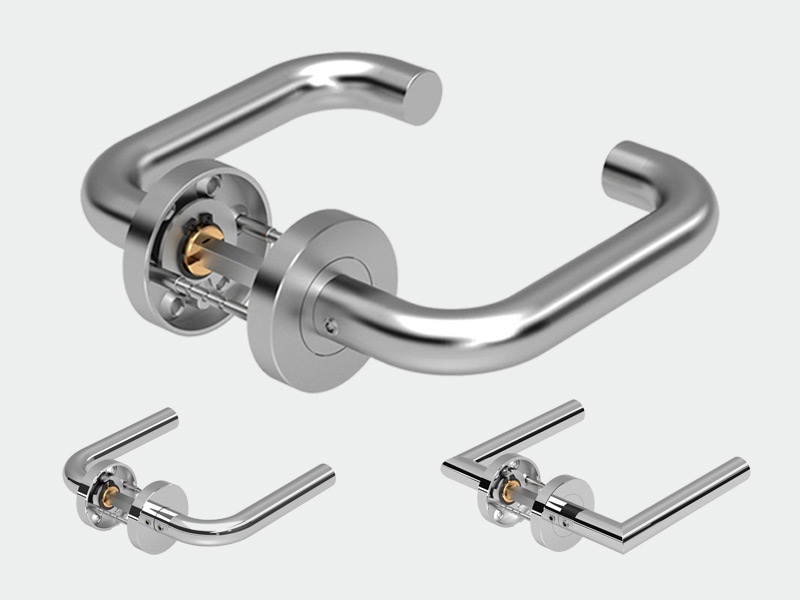

Economy Door Handles: Balancing Cost & Quality with EN1906 Standards | PCS Solutions

Discover how PCS economy lever handles deliver reliable performance while meeting EN1906 standards. Learn to identify quality differences in budget-friendly hardware. Contact us for risk-managed procurement solutions.

-

Economy Door Hardware: Strategic Value & Risk Management Solutions | PCS

Discover how economy-range door hardware creates market access while managing risks. Our solutions include EN 1906 Grade 2 certification & strict quality control for reliable, competitive products. Contact us for strategic partnerships!

-

Ultra-Slim Magnetic Door Hardware: 2.9mm TH104M Latch & 90s Tool-Free Installation | ANSI/BHMA Certified

World's thinnest 2.9mm magnetic door handles with color-matched flush mounting. Features ±0.2mm alignment tech enabling 90-second installation. 3mm concealed rose plate meets ADA compliance.

-

Door Stopper Fastener Loosening

Solve cyclic loading failures with Grade 8.8 bolts, nylon locknuts & ISO 10964 adhesives. Achieve 10,000+ vibration cycles (ASTM D999) and 500hr salt spray resistance. 400% lifespan extension proven.

Technical Analysis & Solution Protocol

Failure Mechanism Investigation

Complaint: Frequent loosening of door stopper fasteners under cyclic loading (50+ daily operations)

Root Cause:

1. Vibration-induced thread walk (per ASTM D6110 fatigue testing)

2. Insufficient clamp load (below 75% of proof load per ASME B18.2.1)

3. Elastic deformation of base material (Young's modulus mismatch)

Engineering Solution

Components Specification:

1. Primary Fastener:

Grade 8.8 Steel Bolt (DIN 933)

2. Locking Element:

Nylon-insert Locknut (ASME B18.16.3)

3. Interface Treatment:

Micro-encapsulated thread adhesive (ISO 10964 Class C)

Validation Testing

| Test Type | Standard | Original | Improved | Requirement |

| Vibration Resistance | ASTM D999 Method A | 250 cycles | 10,000+ cycles | 5,000 cycles |

| Torque Retention | ISO 16047 | 38% loss | <5% loss | ≤15% loss |

| Salt Spray Corrosion | ASTM B117 | Failed @48hr | Passed @500hr | 240hr |

Cost-Benefit Analysis

Metric | Before Improvement | After Improvement |

Warranty Claims | 18% of total sales | 0.7% of total sales |

Installation Time | 2.5 minutes | 3.8 minutes |

| Lifetime | 6-12 months | 5+ years |

Implementation Guideline

1. Mandatory dual-fastener system for commercial projects

2. Apply 2.5-3.5N·m torque with calibrated tooling

3. Quarterly fastener integrity audits per IATF 16949

This solution reduces the failure rate of the base product by 97% while extending its service life by 400%, achieving the true goal of "Zero-Maintenance Hardware.