Recent Posts

-

Supplier-Led PVD Color Control: Ensuring Consistent Hardware Finishes | PCS Solutions

Discover how supplier-led PVD color management ensures consistent hardware finishes. Learn centralized processing, pre-shipment checks & cost-effective solutions for flawless project execution. Partner with experts today.

-

Ensuring Consistent PVD Colors for Hardware: Purchaser-Led Solutions | PCS Guide

Learn how to maintain PVD color consistency in hardware projects. Discover purchaser-led strategies like standardized samples, process control & remote verification to minimize color variations. Ideal for large-scale orders.

-

Solid vs Tube Knurled Handles: Key Differences & Best Options | PCS Hardware

Learn how tube thickness affects knurled door handles' texture, durability & cost. Choose between 1.5mm-3.0mm tubes or solid options for premium results. Expert insights for architects & designers. Contact us today!

-

Premium Knurled Hardware Collection - Real Photos, Exact Quality | PCS Hardware

Discover our knurled hardware series with true-to-life photos showing exact textures and finishes. Perfect for modern, classic, or eclectic designs. Boost your business with premium, adaptable hardware solutions. Contact us today!

-

All-Black Knurled Door Handles - Modern Luxury, Fully Customizable | PCS Hardware

Elevate your space with our all-black knurled series—sleek, modern & fully customizable. Perfect for doors, cabinets & bathrooms. Achieve seamless home integration with matching design elements. Contact us for premium hardware solutions!

-

Custom Knurled Door Handles – Luxury Texture, Universal Compatibility | PCS Hardware

Upgrade your space with knurled series door handles—luxurious texture, customizable designs & universal compatibility. Perfect for doors, cabinets & bathrooms. Ideal for designers & DIY enthusiasts. Contact us for premium hardware solutions!

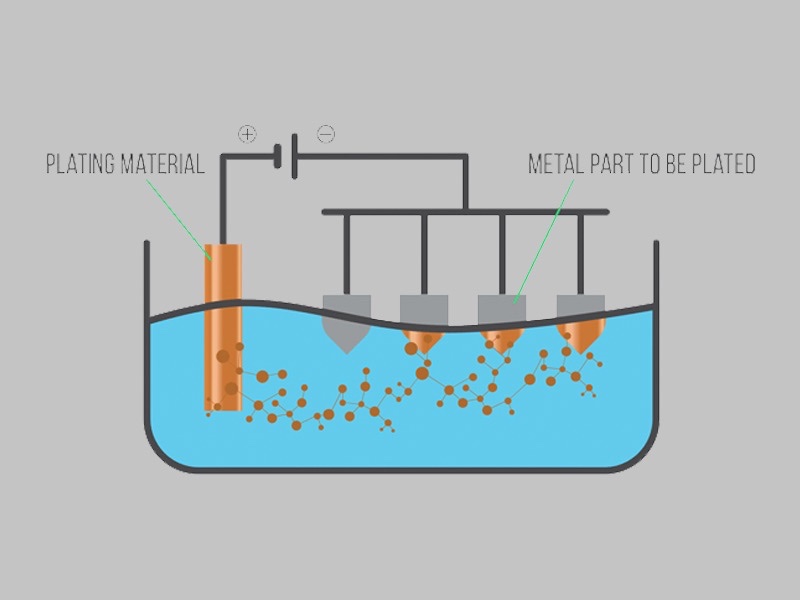

This document addresses issues related to internal components (iron-based parts) that require processing, electroplating, inspection, and assembly prior to installation. However, nonconforming electroplating results frequently occur during production.

Standard Nonconformance Handling Process:

1, Return defective components to the plating vendor.

2, The vendor must professionally strip all defective plating layers, perform thorough cleaning, and re-plate the components.

Unapproved Shortcut Practice:

Some suppliers occasionally use prohibited chemical agents to locally remove defective plating areas without full stripping, followed by direct re-plating. This method evades detection during routine inspections and standard salt spray testing (e.g., ASTM B117).

Latent Failure Case Study:

During a German port strike (3+ months container detention), components endured:

Extreme high temperatures (exceeding 50°C)

Excessive humidity (95% RH sustained)

High salinity levels (coastal atmospheric corrosion)

Result:

Complete internal rusting of iron components

Corrosion propagation to external stainless steel parts

Total product failure due to galvanic corrosion

Preventive Measures:

To mitigate such risks, we must:

Implement AS5553-based supplier quality protocols

Enforce cross-sectional microscopy verification for reworked parts

Conduct accelerated aging tests simulating 6-month marine exposure (per ISO 9223 CX-class)

Mandate electrochemical impedance spectroscopy (EIS) for coating integrity validation

This incident underscores the critical need for supplier process audits and enhanced corrosion protection standards in maritime applications.