Recent Posts

-

Supplier-Led PVD Color Control: Ensuring Consistent Hardware Finishes | PCS Solutions

Discover how supplier-led PVD color management ensures consistent hardware finishes. Learn centralized processing, pre-shipment checks & cost-effective solutions for flawless project execution. Partner with experts today.

-

Ensuring Consistent PVD Colors for Hardware: Purchaser-Led Solutions | PCS Guide

Learn how to maintain PVD color consistency in hardware projects. Discover purchaser-led strategies like standardized samples, process control & remote verification to minimize color variations. Ideal for large-scale orders.

-

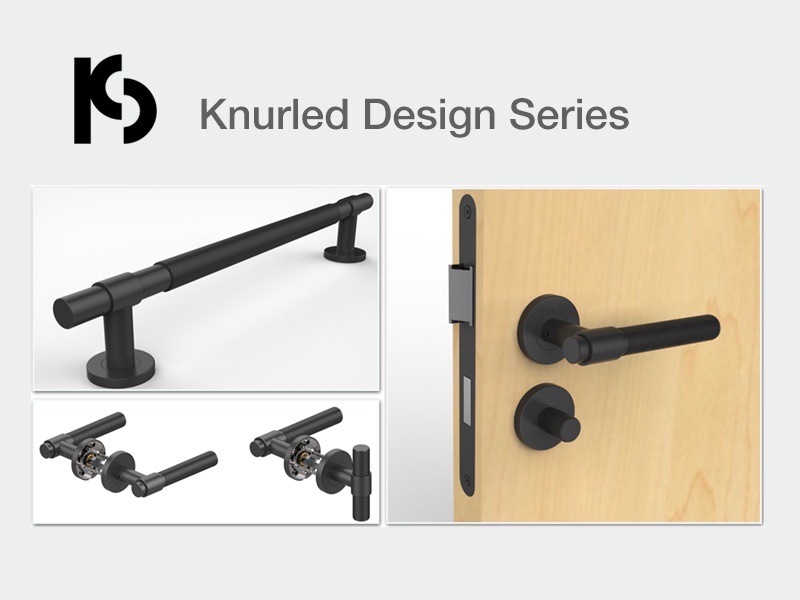

Solid vs Tube Knurled Handles: Key Differences & Best Options | PCS Hardware

Learn how tube thickness affects knurled door handles' texture, durability & cost. Choose between 1.5mm-3.0mm tubes or solid options for premium results. Expert insights for architects & designers. Contact us today!

-

Premium Knurled Hardware Collection - Real Photos, Exact Quality | PCS Hardware

Discover our knurled hardware series with true-to-life photos showing exact textures and finishes. Perfect for modern, classic, or eclectic designs. Boost your business with premium, adaptable hardware solutions. Contact us today!

-

All-Black Knurled Door Handles - Modern Luxury, Fully Customizable | PCS Hardware

Elevate your space with our all-black knurled series—sleek, modern & fully customizable. Perfect for doors, cabinets & bathrooms. Achieve seamless home integration with matching design elements. Contact us for premium hardware solutions!

-

Custom Knurled Door Handles – Luxury Texture, Universal Compatibility | PCS Hardware

Upgrade your space with knurled series door handles—luxurious texture, customizable designs & universal compatibility. Perfect for doors, cabinets & bathrooms. Ideal for designers & DIY enthusiasts. Contact us for premium hardware solutions!

How to ensure consistent PVD colors for supporting hardware products? - 1/2

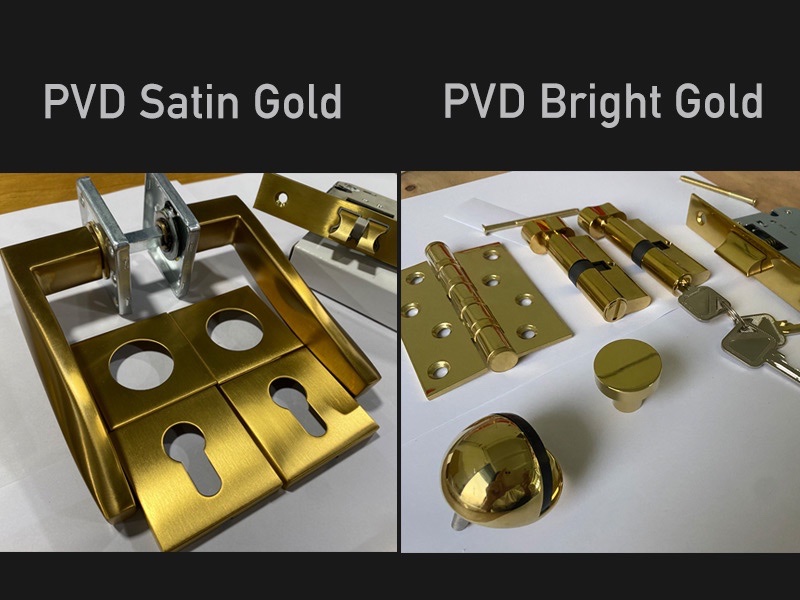

The PVD (Physical Vapor Deposition) process is affected by multiple factors such as the manufacturer, equipment, temperature, and heating duration, often causing color variations.

Taking the relatively stable PVD gold color as an example, even within the category of "gold," the shades produced by different processes can vary in terms of lightness, darkness, and hue. When products from different suppliers are used in the same project or even on the same door, the issue of color differences becomes particularly prominent, leading to quality complaints.

To address this challenging problem, we can start from two main perspectives: the purchaser-led approach and the supplier-led approach.

Purchase - Led approach

Step 1. Standardize uniformly: The purchaser formulates a color sample and distributes it to all suppliers, requiring them to sign for and confirm the color standard sample, which will serve as the production benchmark.

Step 2. Process control: Before production or before shipment, the purchaser arranges quality inspectors to conduct on-site verification to check whether the bulk goods are consistent with the color standard sample, and promptly identify and correct any color difference issues.

Step 3. Remote verification: If on-site quality inspection is not possible, suppliers can be required to send samples of the bulk goods before shipment for centralized comparison of color differences.

Pros: Since the suppliers produce their own products, the procurement cost is relatively low.

Cons: The purchaser needs to invest a great deal of time and effort in follow-up work. Moreover, the process differences among different manufacturers are difficult to completely eliminate. If color differences occur and rework is required, not only will the cycle be long, but it may also seriously affect the scheduled delivery progress.

Ideal for: Suitable for super-large orders of a single project or long-term orders with continuous repeat orders.