Recent Posts

-

Supplier-Led PVD Color Control: Ensuring Consistent Hardware Finishes | PCS Solutions

Discover how supplier-led PVD color management ensures consistent hardware finishes. Learn centralized processing, pre-shipment checks & cost-effective solutions for flawless project execution. Partner with experts today.

-

Ensuring Consistent PVD Colors for Hardware: Purchaser-Led Solutions | PCS Guide

Learn how to maintain PVD color consistency in hardware projects. Discover purchaser-led strategies like standardized samples, process control & remote verification to minimize color variations. Ideal for large-scale orders.

-

Solid vs Tube Knurled Handles: Key Differences & Best Options | PCS Hardware

Learn how tube thickness affects knurled door handles' texture, durability & cost. Choose between 1.5mm-3.0mm tubes or solid options for premium results. Expert insights for architects & designers. Contact us today!

-

Premium Knurled Hardware Collection - Real Photos, Exact Quality | PCS Hardware

Discover our knurled hardware series with true-to-life photos showing exact textures and finishes. Perfect for modern, classic, or eclectic designs. Boost your business with premium, adaptable hardware solutions. Contact us today!

-

All-Black Knurled Door Handles - Modern Luxury, Fully Customizable | PCS Hardware

Elevate your space with our all-black knurled series—sleek, modern & fully customizable. Perfect for doors, cabinets & bathrooms. Achieve seamless home integration with matching design elements. Contact us for premium hardware solutions!

-

Custom Knurled Door Handles – Luxury Texture, Universal Compatibility | PCS Hardware

Upgrade your space with knurled series door handles—luxurious texture, customizable designs & universal compatibility. Perfect for doors, cabinets & bathrooms. Ideal for designers & DIY enthusiasts. Contact us for premium hardware solutions!

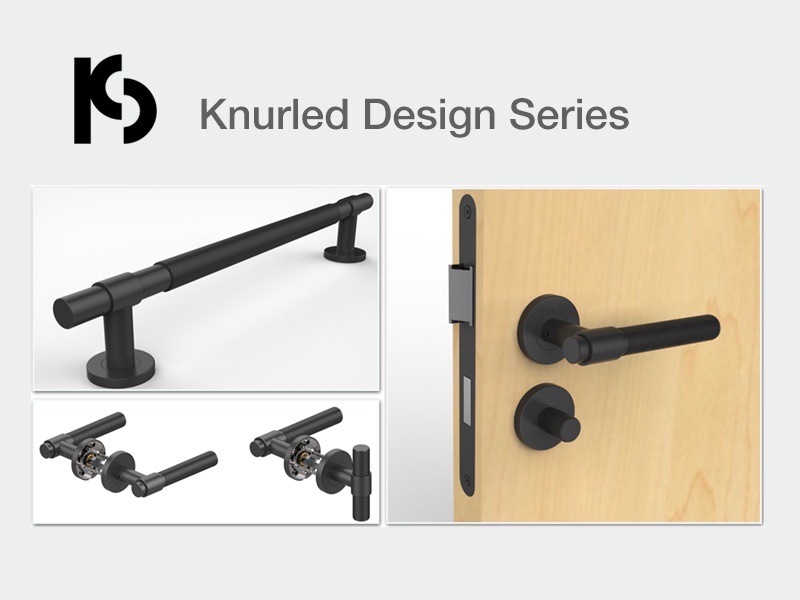

Can you spot the difference between a solid and a tube in the picture?

Knurled erirs extension introduction

Knurling Process

Knurling uses special tools to create patterns. When making door handles, the thickness of the tube material affects the knurling outcome.

Thin tubes can deform under knurling pressure. Thus, we need to precisely control pattern depth and clarity to avoid over - extrusion that could damage or deform the tube wall, ruining both appearance and usability. Thick tubes, on the other hand, can withstand more rolling pressure, enabling deeper, clearer, and more three - dimensional patterns with better stability.

Choosing the best Knurling item & Its Options

In essence, the best choice is what the market favors in appearance.

A thicker tube results in a clearer, more delicate texture and a better look, but at a higher cost.

A thinner tube has a relatively shallower texture and a smoother feel, with the advantage of lower cost.

Available thicknesses are

1.5mm, 2.0mm, 3.0mm for tubes, and fully solid.

To have an in-depth discussion with us. pls contact

Email: [email protected].

WhatsApp: 0086-13822444943