Recent Posts

-

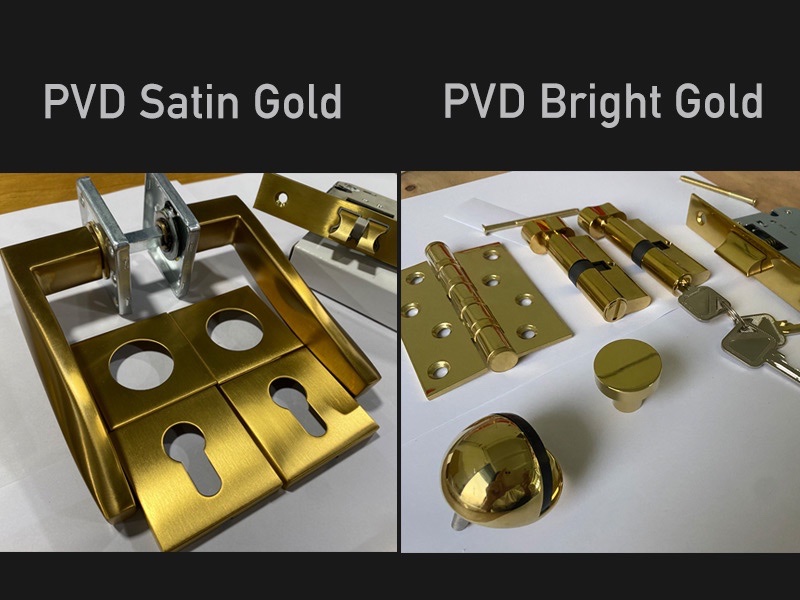

Supplier-Led PVD Color Control: Ensuring Consistent Hardware Finishes | PCS Solutions

Discover how supplier-led PVD color management ensures consistent hardware finishes. Learn centralized processing, pre-shipment checks & cost-effective solutions for flawless project execution. Partner with experts today.

-

Ensuring Consistent PVD Colors for Hardware: Purchaser-Led Solutions | PCS Guide

Learn how to maintain PVD color consistency in hardware projects. Discover purchaser-led strategies like standardized samples, process control & remote verification to minimize color variations. Ideal for large-scale orders.

-

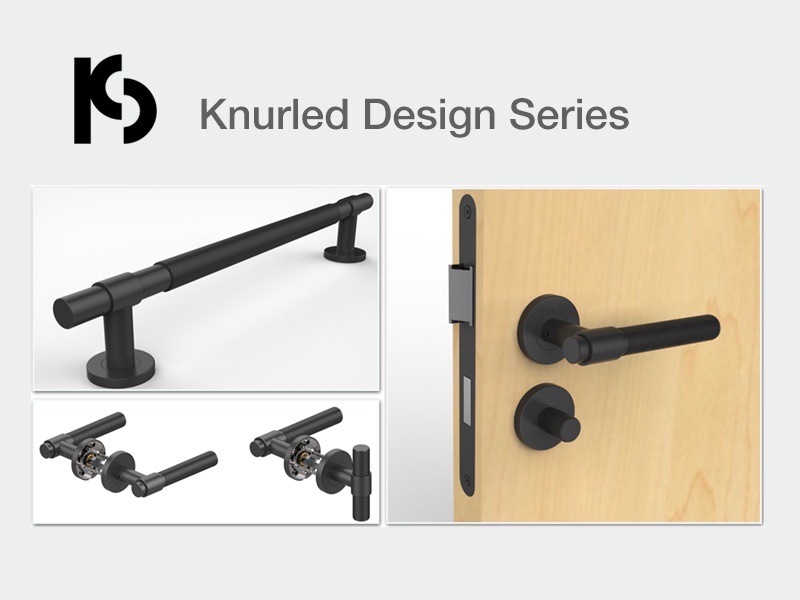

Solid vs Tube Knurled Handles: Key Differences & Best Options | PCS Hardware

Learn how tube thickness affects knurled door handles' texture, durability & cost. Choose between 1.5mm-3.0mm tubes or solid options for premium results. Expert insights for architects & designers. Contact us today!

-

Premium Knurled Hardware Collection - Real Photos, Exact Quality | PCS Hardware

Discover our knurled hardware series with true-to-life photos showing exact textures and finishes. Perfect for modern, classic, or eclectic designs. Boost your business with premium, adaptable hardware solutions. Contact us today!

-

All-Black Knurled Door Handles - Modern Luxury, Fully Customizable | PCS Hardware

Elevate your space with our all-black knurled series—sleek, modern & fully customizable. Perfect for doors, cabinets & bathrooms. Achieve seamless home integration with matching design elements. Contact us for premium hardware solutions!

-

Custom Knurled Door Handles – Luxury Texture, Universal Compatibility | PCS Hardware

Upgrade your space with knurled series door handles—luxurious texture, customizable designs & universal compatibility. Perfect for doors, cabinets & bathrooms. Ideal for designers & DIY enthusiasts. Contact us for premium hardware solutions!

Standard Rework Protocol

1.Nonconformance Identification

Failed components undergo ASTM B117 salt spray testing (72hrs minimum)

2. Full-Strip Reprocessing

Certified stripping using EN 12540-compliant chemical baths

Three-stage ultrasonic cleaning (DI water > Alkaline > Acidic)

3. Re-plating Verification

Cross-section microscopy to validate base metal integrity

Adhesion testing per ISO 2819 (≥8MPa required)

Unapproved Shortcut Practice

Illegitimate Process Flow:

Contravenes RoHS Directive 2011/65/EU Article 4(1)

Latent Defect Characteristics:

Initial QA screening passes standard 240hr NSS testing

Accelerated failure occurs under:

85°C/85%RH thermal humidity cycling (IEC 60068-2-30)

90 days marine atmosphere exposure (ISO 9223 CX class)

Case Study: Hamburg Port Incident

Parameter | Specification | Field Condition |

Temperature | 25°C max | 58°C (Container black box data) |

Relative Humidity | 60% RH max | 98% RH sustained |

Chloride Deposition | 0.3mg/m²/day | 2.1mg/m²/day |

| Exposure Duration | 30-day limit | 117 days |

Failure Mechanism:

Subsurface corrosion initiated at stripped micro-cracks (SEM-EDS analysis confirmed Cl⁻ penetration depth >500μm)

Corrective Actions

Implement AS5553 counterfeit parts prevention protocol

Mandatory 1000hr extended salt spray testing for marine applications

Establish electrochemical impedance spectroscopy (EIS) monitoring